Iitships ze-semiconductor zisisiseko setekhnoloji yolwazi kunye netekhnoloji ebalulekileyo esakhasayo kunye noshishino amazwe akhuphisanayo ukuluphuhlisa.Isonka esisicaba, njengezixhobo ezisisiseko zokwenza iitships ze-semiconductor, idlala indima ebaluleke kakhulu kuphuhliso lweshishini le-semiconductor laseTshayina. Ngokuphathelele amandla okuvelisa ii-wafer, iTshayina sele ikhokela kwihlabathi liphela, kodwa njengoko "ukunqongophala kweetships" kwihlabathi liphela kusanda, kuya kukhawulezisa ngakumbi ukwandiswa kwamandla.

1. Imvelaphi yeProjekthi

Isebe leqela eliphantsi kweqela elibhalisiweyo leshishini le-semiconductor lasekhaya, njengomdlali ophambili kushishino lwezixhobo zolwazi lwe-elektroniki lukazwelonke, lizibophelele kuphando nophuhliso, ukuveliswa kwezixhobo ze-semiconductor, izixhobo ezikhethekileyo ze-elektroniki, izixhobo ze-semiconductor kunye nezinye iitekhnoloji. Imveliso ephambili yi-semiconductor zone melting single crystal silicon wafer, enegunya eliphambili kwihlabathi liphela kunye nesabelo semarike yasekhaya yengaphezulu kwe-80%.

Ukuze kukhawuleziswe ukwanda kwamandla, inkampani ityale imali emalunga ne-$3 yeebhiliyoni ukuqalisa ukwakhiwa kweprojekthi enkulu yokuvelisa kunye nokuvelisa i-silicon wafer enobubanzi obukhulu kwiisekethe ezidibeneyo kwiSixeko saseYixing, kwiPhondo laseJiangsu. Isigaba sesibini sale projekthi siqaliswe ngo-2021, sinamathela kwingcamango ephambili ye-"Industry 4.0" kwaye siceba ukusebenzisa imveliso ekrelekrele kulo lonke umgca ukuze kufezekiswe ukwenziwa ngokuzenzekelayo, ulwazi, kunye nokwakhiwa okukrelekrele kweworkshop. Emva kokugqitywa, umthamo wemveliso iyonke uya kuba zii-220000 ze-epitaxial wafers ze-8-intshi, ii-2000000 ze-12-intshi ezipholisiweyo, kunye nee-150000 ze-epitaxial wafers ze-12-intshi ngenyanga, zibe sisiseko semveliso ye-silicon wafer enezibonelelo zehlabathi. Ke ngoko, ngokwendawo yokugcina impahla ekrelekrele yeqela,I-ROBOTECH iphucule ubukrelekrele, ulwazi, kunye nenqanaba lokuzenzekelayo lesiseko sayo semveliso ngokusebenzisa iinkqubo zokugcina izinto ezikrelekrele eziphambili..

2. Iprojekthipukuhlamba

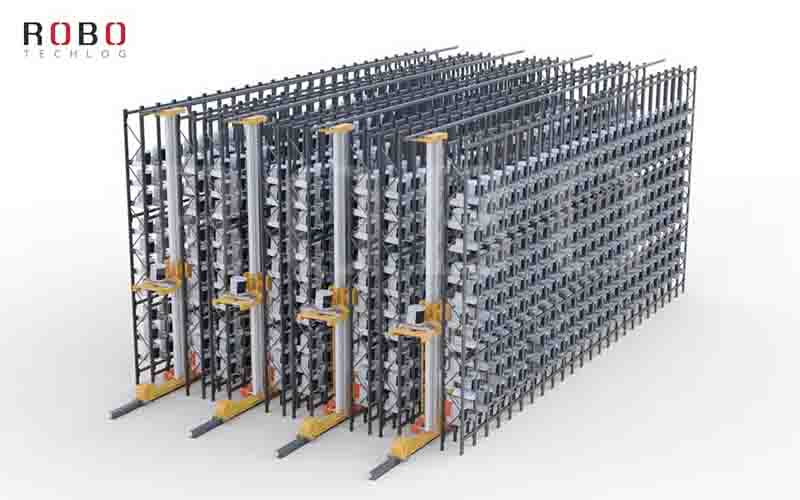

I-ROBOTECH isebenzise ngokupheleleyo indawo ethe nkqo eyi-6m yesiseko sayo semveliso kwaye icwangcise isicwangcisoIndawo yokugcina izinto ezenzekelayo enohlobo lweebhokisi ezineukufikelela kwiimveliso ze-semiconductor wafer, ezinokuthwala isimbuku esingaphezulu kwe-Iindawo zokugcina izinto ezingama-2000, ukwandisa ngempumelelo amandla okugcina ii-wafersNgenxa yokuba i-wafer ikwimo yeshiti, isithwali sayo sithatha isitya seplastiki esibonakalayo esingu-330 * 330 * 300 esenziwe ngokwezifiso ukuze kube lula ukufikelela kwi-wafer, enomthwalo ophezulu we-50kg.Isombulule ingxaki yeenkqubo zokugcina iiwafer ezintsonkothileyo kunye nokusetyenziswa okulinganiselweyo kwendawo kwiindawo zokugcina impahla zemveli, nto leyo eyanceda ekuphuculeni ukusetyenziswa kwendawo nokusebenza kakuhle.

• Inkqubo yekreni ye-Zebra series stacker

• Isantya semveliso se-100m/min kunye ne-24-hour kunye ne-63P/h ngomjikelo ngamnye

Ngokuphathelele ukusebenza kakuhle, iROBOTECH ikhethai-zebra series stackerikreniinkquboukuhamba kwezinto ezinamandla aphezulu, ngesantya esithe tye se100m/ngomzuzu, ehlangabezana neIsigqi semveliso seeyure ezingama-24yesiseko semveliso, kwaye ukusebenza kakuhle kokugcina kunokufikelela63P/h ngomjikelo ngamnye.

3. Akukho mingeni yoyikiso, akukho tshintsho lwenziwe ngokwezifiso

•EQinisekisa uthuli kunye nokumelana nomothuko

•Ukwenziwa ngokwezifiso okungekho semgangathweni

•Uisixhobo senzwa ye-ltrasonic

•TIsithuthi sibekwe kwi-engile yeedigri ezi-5 kwiishelufu nakwiifolokhwe

Umngeni 1

Iimpawu zokugcina ii-semiconductor wafers zeziqinisekisa uthuli kunye nokumelana nokukhwankqiswa, kungenjalo kulula ukwenza umonakalo kwiiwafers ezibuthathaka. Ngokusekelwe koku, iROBOTECH iphucule ulwakhiwo loomatshini lwe-stacker crane ukuzeukwenziwa ngokwezifiso okungekho semgangathweniUmzekelo, kusetyenziswa iireli zomhlaba ze-aluminium alloy endaweni yeereli zesiqhelo, kusetyenziswa iikholamu ze-aluminium alloy ezitsalwa ngamandla aphezulu endaweni yeekholamu zentsimbi, kusetyenziswa amavili agqunywe ngerabha endaweni yeevili zentsimbi, kusetyenziswa ukuphakamisa ibhanti yexesha endaweni yokuphakamisa intambo yentsimbi, kwaye kongezwa izigqubuthelo ezingangeni luthuli kwiqonga lemithwalo.Ukususela kwinqanaba lokuqala loyilo lwezixhobo, impembelelo yothuli kunye nokungcangcazela kwiimpahla incitshisiwe, umngcipheko wongcoliseko kwindawo yokusebenzela engenathuli uncitshisiwe,kwaye isivuno siphucukile. Inqanaba lokucoceka lingahlangabezana neemfuno zokusingqongileyo zeKlasi 1000.

Umngeni 2

Ngenxa yebhokisi yeplastiki ebonakalayo yesithwali se-wafer, izinzwa ze-photoelectric eziqhelekileyo azinakusetyenziswa ekufumaneni imithwalo. I-ROBOTECH iyile ngobuchule i-isixhobo senzwa ye-ultrasonicukufunyanwa kwemithwalo, enokuzibona ngokuzenzekelayo imeko yeempahla kwiishelufu nakwiipalethi. Kwaye ixhotyiswe ngekhamera kunye nesikrini sokusebenza ngesandla esiphathwayo ukuze kufezekiswe ukubonakala ngokuchanekileyo kunye nokulandeleka kwazo zonke izixhobo kuyo yonke inkqubo, ngelixa ikwasombulula iingxaki kwaye isombulula iimpazamo ngendlela elula ngakumbi.

Umngeni3

Ukuthintela i-wafer ukuba ingatyibiliki kwisitya esithwalayo,umthwali ubekwe kwi-engile yeedigri ezi-5 kwiishelufu nakwiifolokoIndawo echanekileyo kakhulu kunye nefolokhwe ezinzileyo kuphunyezwa ngokufaka indawo esezantsi yebhokisi ye-wafer kwiiphini ezintathu zokubeka zesixhobo esikhethekileyo sokufaka iqonga lemithwalo yomoya ukuze igcinwe. Emva kovavanyo oluphindaphindwayo, ukuchaneka kokugqibela kwendawo kufikelele kwi± 2mm, kwaye ukugudama kwefolokhwe kufikelele99.99%Ukongeza, izixhobo zisebenzisa izixhobo ezahlukeneyo zokuqhagamshela, nto leyo ephucula ngempumelelo umgangatho wazo zonkeuzinzo kunye nokhuseleko.

Njengengcali kwizisombululo zokugcina izinto ezizenzekelayo, iROBOTECH yakhe izisombululo zezothutho ezikrelekrelekwizixhobo ze-wafer ezingenangcoliseko kwaye ezilandelekayo ngexesha langempela, ngokusekelwe kwizixhobo eziphambili kunye neenkqubo ezibanzi.

Ukuphunyezwa ngempumelelo kwale projekthi kubonisaimpumelelo esebenzayo kwisitoreji ezenzekelayo se-semiconductor wafer, kwaye ikwathetha ukubaI-ROBOTECH iza kungena ngokusesikweni kwicandelo le-semiconductor, enika amandla amashishini e-semiconductor ngezisombululo ezikrelekrele zokuzenzekelayo kwe-logistics. Kwixesha elizayo, i-ROBOTECH iya kuqhubeka nokuhlola, iqokelela ulwazi lweshishini, iphucule ukusetyenziswa kwezixhobo, kwaye ifezekise ukuphuculwa kokusebenza kakuhle ngokubanzi.

Izixhobo zokugcina ulwazi zeNanJing Inform (Group) Co.,Ltd

Ifowuni ephathwayo: +86 25 52726370

Idilesi: No. 470, Yinhua Street, Jiangning District, Nanjing Ctiy, China 211102

Iwebhusayithi:www.informrack.com

I-imeyile:[i-imeyile ikhuselwe]

Ixesha lokuthumela: Epreli-11-2023